DynaGROUP Technologies

A full range of industrial products and services

The solution to your needs for mechanical integration, industrial environment control, product handling and many more! Contact us for more information!

We design and manufacture dust collectors that meet your specific needs. In addition, we modify your existing dust collectors in order to optimize their overall capacity using various advanced technologies.

Our team of experts will assist you in the development of your projects. As a mechanical integrator, we combine various techniques allowing us to achieve a result that meets your specific needs.

We design systems for material conveying, both pneumatically and mechanically. Our engineers will offer you the most functional and economical solution according to your needs in product handling.

Our team or expert targets the best opportunities offered by the various grant programs and develops a strategy that maximizes the amount allocated.

If your project qualifies, we take charge of the production of your tax credit claim for SR&ED which helps you considerably reduce the cost of your project.

Our technical team takes on the installation of any new system, whether supplied by us or others. We offer management and coordination of all work.

Our technical team carries out a complete evaluation of your existing systems. Then, our engineering department will provide our recommendations in order to improve the performance of your systems.

Our technical team will assist you promptly and efficiently during mechanical breakdown of your equipment by providing you with the necessary parts and services.

Dust collection system with a capacity of 80,000 CFM for an asphalt plant with a capacity of 300 mT / hr. The system was delivered complete with structure, fully insulated dust collector / knocking box, fan, pipes and exhaust stack.

Mobile dryer for aggregate, incorporating a dust collector of 25,000 CFM in mobile configuration - the system is completely independent and can be moved if necessary. Integrates the dryer, the capture device, the pipes, the dust collector, the fan and a removable chimney, all on a semi-trailer.

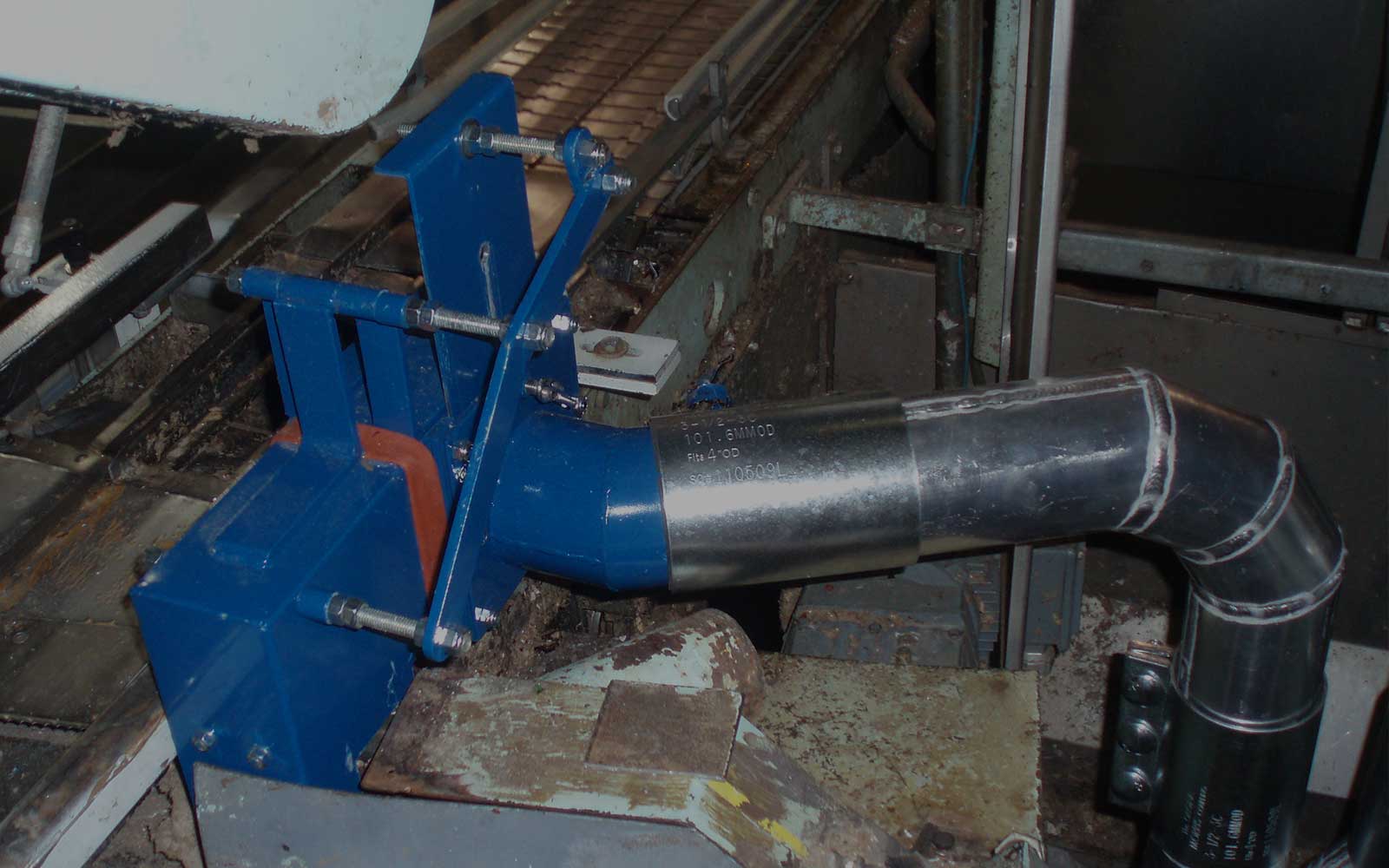

Source capture system on mechanical conveyors, including containment and removable lid for each conveyor. Each capture point connects to a suction network connected to a central dust collector.

Suction system for a dryer in an asphalt plant. The system was delivered with a capture device specially adapted for the dryer, a "knocking box" type pre-separator, a dust collector, its structure, the fan, the ducting and the chimney.

Source capture system for preparation / painting room. We have specially designed removable arms integrating the connection points for vacuum systems, breathing air and compressed air for tools. The vacuum system is connected to a central dust collector and the arms are controlled by a compressed air system.

Replacement of an existing dust collector with 5 smaller units. Each unit is fully independent and integrated, including the support structure, fan, inter-component ducting, explosion protection, including a non-return flap, explosion venting door and blast redirection.

Complete air control system in a bagging plant. Special capture devices have been developed which are adapted to the machines in place. The system was delivered with complete ducting for 42 capture points, all of which are connected to a central dust collector, incorporating a HEPA filtration section to allow recirculation of air in the plant.

Do not hesitate to contact us for any requests or comments.

© 2016 DYNAGROUP TECHNOLOGIES | All Rights Reserved